Light Pole Inspections

Inspecting poles on a routine basis is important. Corrosion, which reduces structural integrity, is inevitable. Light poles, as with any man-made structures, require periodic inspection and maintenance during their service life. All man-made structures, whether manufactured from steel, wood, aluminum, concrete or other materials, are susceptible to decay and eventual failure.

Prevention

Without proper maintenance, the deteriorating effects of the environment over time can reduce the functional life of a light pole and in some cases, cause pole collapse. Corrosion, high winds, metal fatigue, insects, wind-induced vibrations, or an overloading of the structure may damage a pole and lead to failure.

Inspection

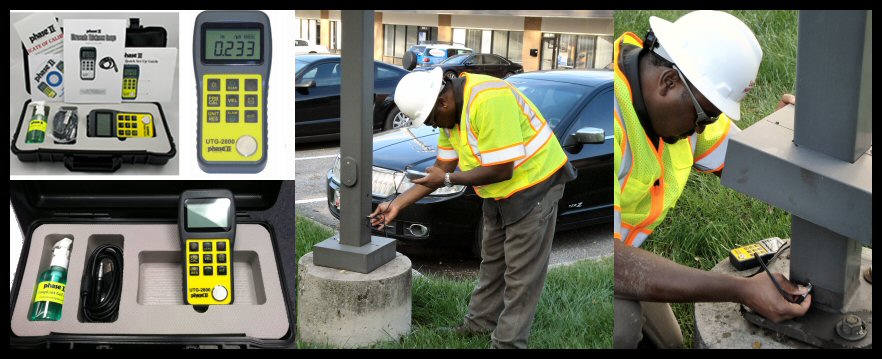

A light pole inspection must include, at minimum, a visual check for structural damage, broken welds, tampering, nut loosening, missing covers, internal or external corrosion, foundation problems, excessive shaft deflection and vibration. In most cases, we perform a punch test at the base of the pole when corrosion is suspected.

Testing and Stray Voltage

All light pole manufacturers require annual inspections of anchor bolts, joints, and base plates to ensure structural integrity. Without proper inspection and maintenance, the deteriorating effects of the environment over time can reduce the life of a light pole and in many cases, cause the pole to fail. Corrosion, high winds, metal fatigue, wind-induced vibrations, and or an overloading of the pole (by banners or flags for example) can lead to failure. LMI performs both a visual and electronic test to ensure the pole has sufficient stability.

However, stability is only part of the danger, Google search “electrical shock by light pole” and you will understand the importance of testing light poles for stray voltage. We perform stray voltage testing with the same meter approved by local utility companies, in fact we perform stray voltage testing for PEPCO and several local government agencies. We recommend annual testing for both structural integrity and touch voltage for every metal light pole. Other electric shock hazards that we test include, sign posts, transformers, fencing, mail boxes, and other metal structures. The cost to have your light poles tested for structural integrity and stray voltage is very affordable. In many cases we can perform both tests for $25.00 per pole.